However, this element does not rust like most other metals.

Like all metals, zinc corrodes when exposed to air and moisture. … And because the zinc covers the screw’s entire exterior, the actual metal from which the screw is made won’t be exposed to moisture or oxygen. Well, zinc can still corrode, but it corrodes at a significantly slower rate than other metals and alloys. And perhaps the biggest reason why brass is superior to zinc is its durability.Īdvertisement Will zinc bolts rust outside? Though with proper laquering or coating, the zinc can be protected from oxidizing effects. Zinc meanwhile is a highly corrosive metal (not an alloy, so its elements cannot be affected to reduce corrosion resistance).

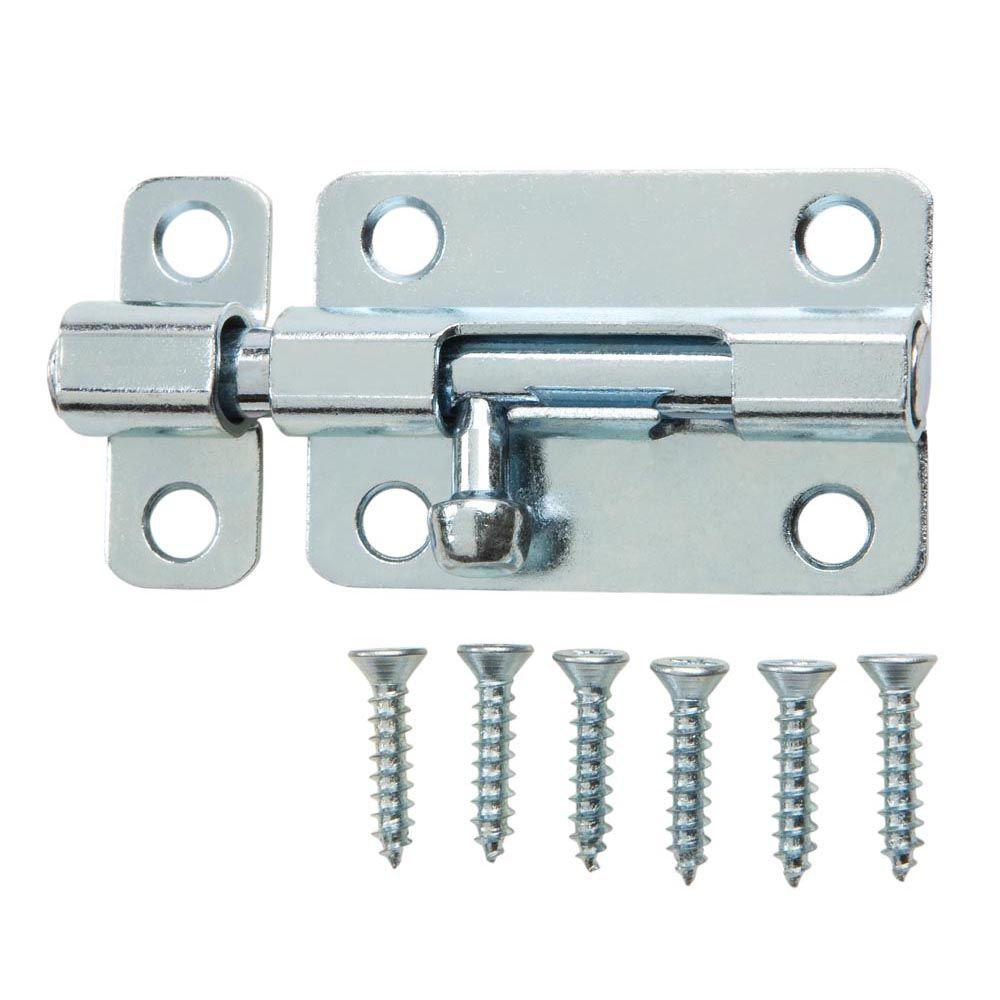

However, zinc is a heavy element, and when alloyed with other metals it provides better corrosion resistance, stability, dimensional strength and impact strength. Though some Zinc alloys can be very strong, overall stainless steel is stronger. … Again, this is due to the fact that it contains chromium, which is stronger and more durable than zinc-covered steel. Much like its counterpart, galvanized steel is also created with the purpose of protecting against rust and corrosion. … After 20 years outdoors a galvanized product will not show signs of rust. Hot dip galvanizing might be 1.0 mil thick – you get over 5 times the protection with galvanizing. The big difference is thickness: zinc plating is normally 0.2 mils thick. Is a galvanized bolt stronger than zinc?īoth zinc plating and galvanizing is an application of zinc plating. This involves coating the surface of a metal with a thin layer of zinc to create a corrosion-resistant barrier. … Nearly one half of all zinc produced is used in zinc galvanizing processes to protect steel and iron from rusting. In its metallic state, zinc is relatively hard and brittle. … Zincsexcellent corrosion resistance in most environments accounts for its successful use as a protective coating on a variety of products and in many exposure conditions. Zinc metal has a number of characteristics that make it a well-suited corrosion protective coating for iron and steel products. Zinc coating is ideal to prevent tarnishing as it corrodes 100x slower than other metals. The barrier it produces stops moisture from penetrating the base metal, preventing rust. Why is zinc good for coating?Ĭoating metal with Zinc increases the life-span of the underlying metal by creating a physical barrier. Its main advantage is it is cheaper and easier to weld. While is does provide some rust protection, its thinner coating is not as rust resistant as hot dip galvanising. Zinc plating (also known as electro-galvanising) is a process where zinc is applied by using a current of electricity. Which is better zinc plated or galvanized? Zinc-plated bolts and hardware fittings, such as gate hinges, will not provide adequate protection from corrosion, and usually do not last beyond 12 months in outdoor settings such as urban coastal environments. Zinc-plated coatings are not suitable for applications exposed to outdoor atmosphere. How long will zinc plated bolts last outside? No other corrosion resistant coating will be as inexpensive as zinc plating though. Zinc plating is rarely sufficient for exposed outdoor use, especially in a marine environment. Are zinc plated bolts good for outdoor use? It also has a high-temperature tolerance up to 120℉ while increasing the metal’s life expectancy. Protection: Zinc plating is corrosion-resistant that slows rusting up to 30 years by keeping out the moisture lingering in air molecules. Is a galvanized bolt stronger than zinc?.Which is better zinc plated or galvanized?.How long will zinc plated bolts last outside?.Are zinc plated bolts good for outdoor use?.

0 kommentar(er)

0 kommentar(er)